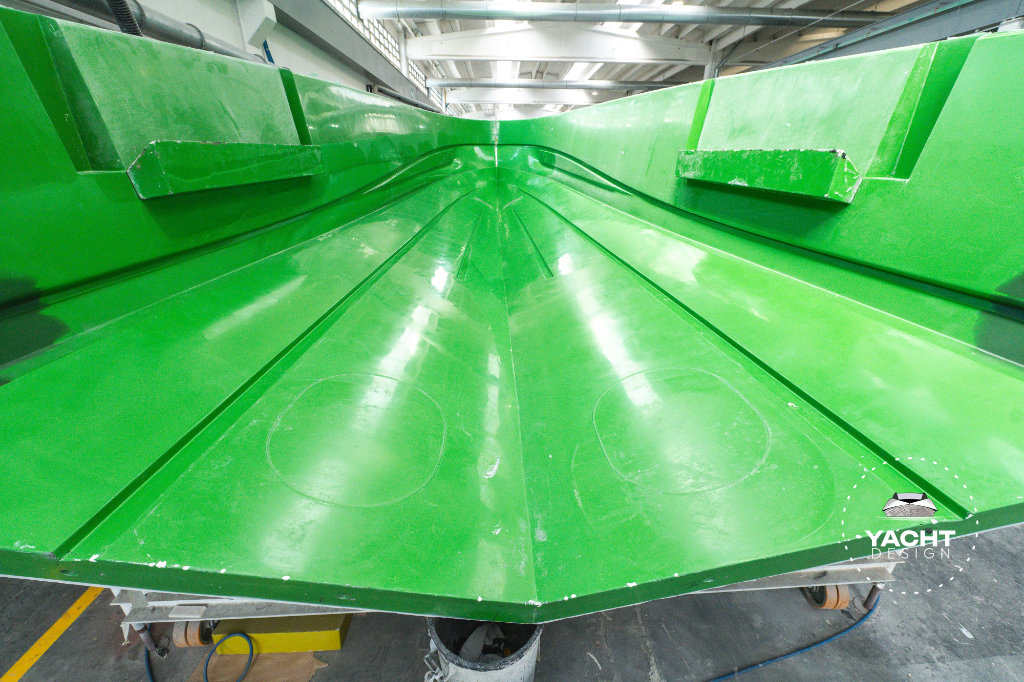

To create any object in composite material, it is essential to have a mold on which to shape the desired product. The mold precisely defines the shape, dimensions, and characteristics of the final piece, ensuring a uniform and repeatable result.

The starting point for mold construction is the master model, which serves as the primary reference. This model must be made at a 1:1 scale, faithfully reproducing every detail of the final object. The quality of the master model directly affects the accuracy of the mold and, consequently, the success of the composite product.

The choice of materials for the model and the mold depends on the final application, the complexity of the geometry, and the number of pieces to be produced. Often, materials such as resins, foams, wood, or metals are used for the master, while molds can be made of fiberglass, carbon fiber, or other advanced composites.

Accurate design and precise manufacturing of the master model are therefore essential to obtaining high-quality molds and final products that meet the required standards.